No matter if standard or bespoke material formulation, with biocomposites from FluidSolids you can substitute a great range of components and products that were until now made from standard, petroleum-based plastics. Additionally, you can develop brand-new parts for consumer electronics, packaging, furniture, load-bearing and structural elements, single use products and many more.

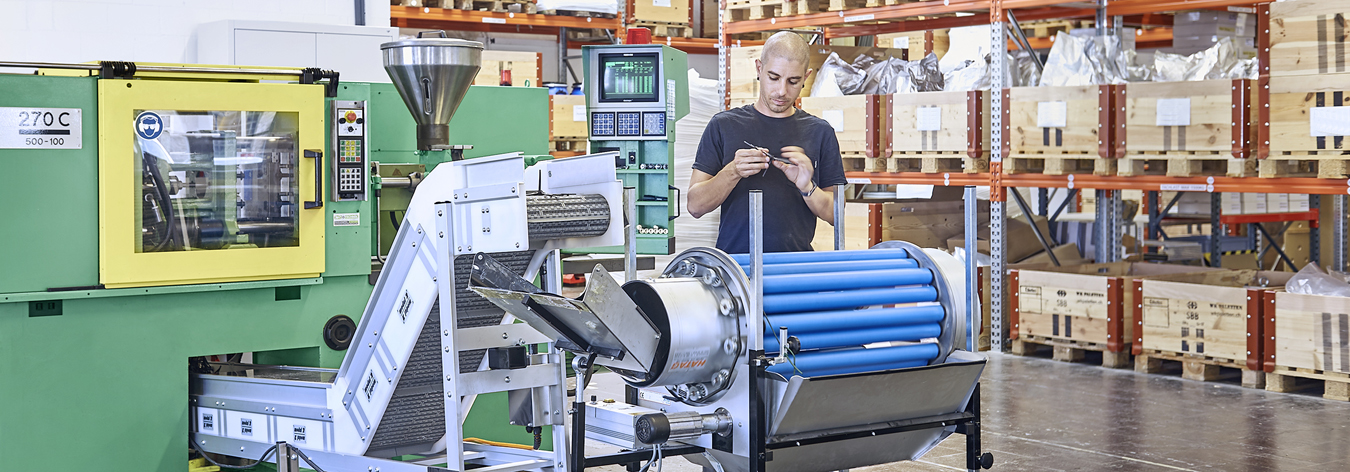

Tools developed by our own engineers

FluidSolids Ltd. develops the tools required for the manufacturing of components and products made from FluidSolids® in-house as specific know-how is needed to meet the material properties. Qualified external tool makers machine the tools – in Swiss quality.

Food industry

Product: Scoop / Measuring spoon

Project: Serial production

Client: ABInBev / Evergrain

Design: Shibuleru

Food industry

Product: Single-use cutlery

Project: Serial production

Client: Pumpstation Gastro GmbH

Design: Shibuleru

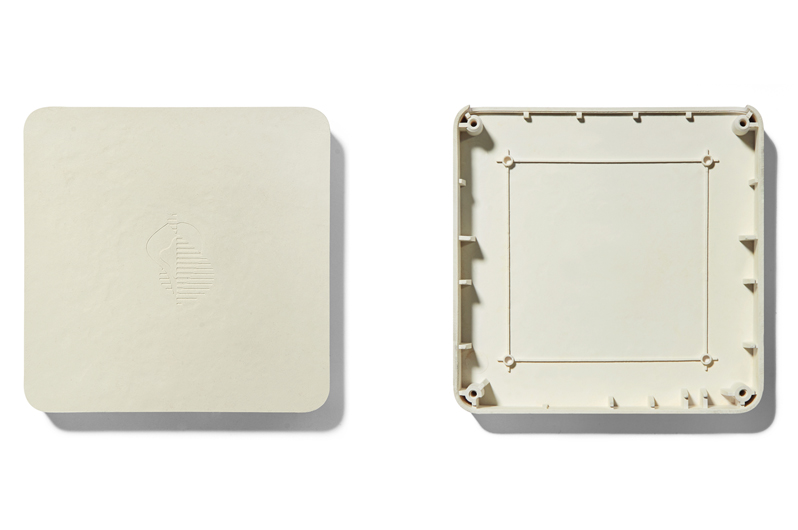

Electronics industry

Product: ICT housing

Project: Pilot production

Client: Swisscom AG

“FluidSolids and Swisscom are committed to a more circular economy. Together, the two companies are working to replace traditional plastics in ICT hardware with sustainable materials.”

Packaging industry

Product: Sock hanger

Project: Serial production

Client: DillySocks AG

Promotional industry

Product: x-mas tree decoration

Project: Serial production

Client: PICC

Building industry

Product: Single-use tool

Project: Serial production

Client: TRM / Gerhard Moser

Fashion industry

Product: Belt hanger

Project: Serial production

Client: ECCO®