The use of FluidSolids® biocomposites to produce components and products is highly cost-effective, as it addresses three cost drivers: savings on material procurement, transport and waste disposal! And because you are reusing waste materials normally disposed of unsustainably, you are reducing your environmental impact during production, processing, recycling and disposing.

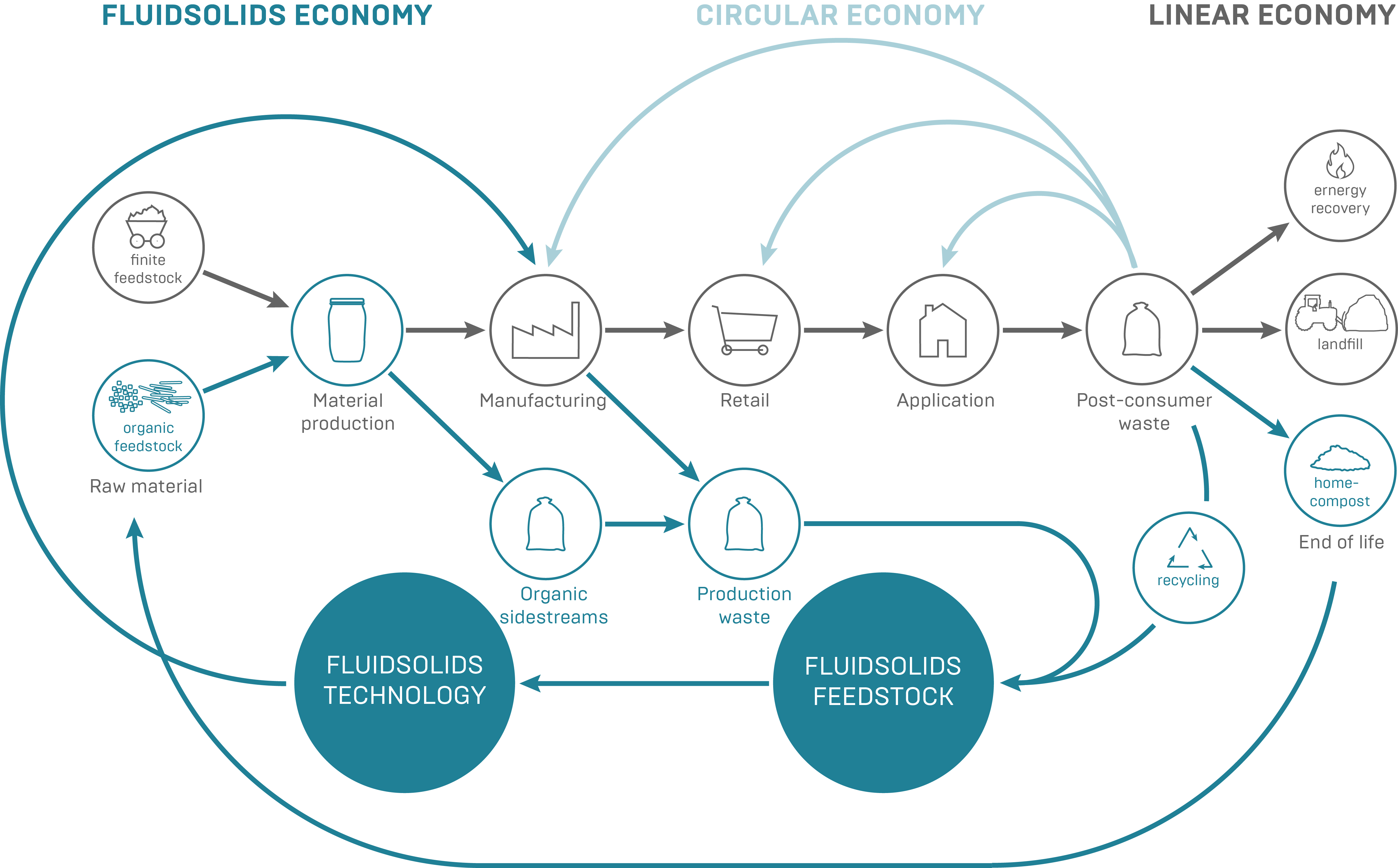

Adding a cycle using residuals

Boost the circular economy

The technology developed by FluidSolids starts where other business operations end: it makes use of biomass residuals, the by-products of the production processes, and adds a brand-new production cycle to the circular economy.

4x

the size of Germany

“Great Pacific Garbage Patch” is the name of a floating mass of garbage which looks like an island and is floating between Hawaii and California. A latest study puts its size at 1.6 million square metres – that’s 4 x the size of Germany.

(Source: www.nature.com)

80%

CO2 reduction

The substitution of petroleum-based plastic with FluidSolids allows – depending on the type of plastic – CO2 savings of 60 to 80%. (Source: FS LCA Study / myclimate)

1%

Of the global demand for plastics

If only 10% of the paper and cardboard waste which ended up in US landfill in 2014 were made into FluidSolids, 1% of the global demand for plastic could be met.

(Source: www.epa.gov)

Reducing costs and carbon footprint

Production waste and products made of FluidSolids® biocomposites may be used again at the end of their life-cycle – simply add them to virgin materials and reprocess them. Any waste that you don’t add to recycling may be composted or incinerated in an energy-from-waste plant yielding additional revenue.

By implementing the FluidSolids technology into your production process you are complementing the circular economy by adding an extra cycle that not only saves costs but truly improves your operation’s carbon footprint.